I've finally gotten a line on a machine shop to do work on the engine, if I can ever just get it up there. They come highly recommended by a couple of different people, so I guess I'll eventually give them a whirl. I called them up, and their estimate is ~$1600 to do the work I think I need.

It's a nice day out. I figured I'd go ahead and finish the teardown while I'm hoping to find some time to get things up to the machine shop. It needs to be done. Today, It's cam & lifters to come out. I pulled the valves a long time ago, and the engine started today in just that state.

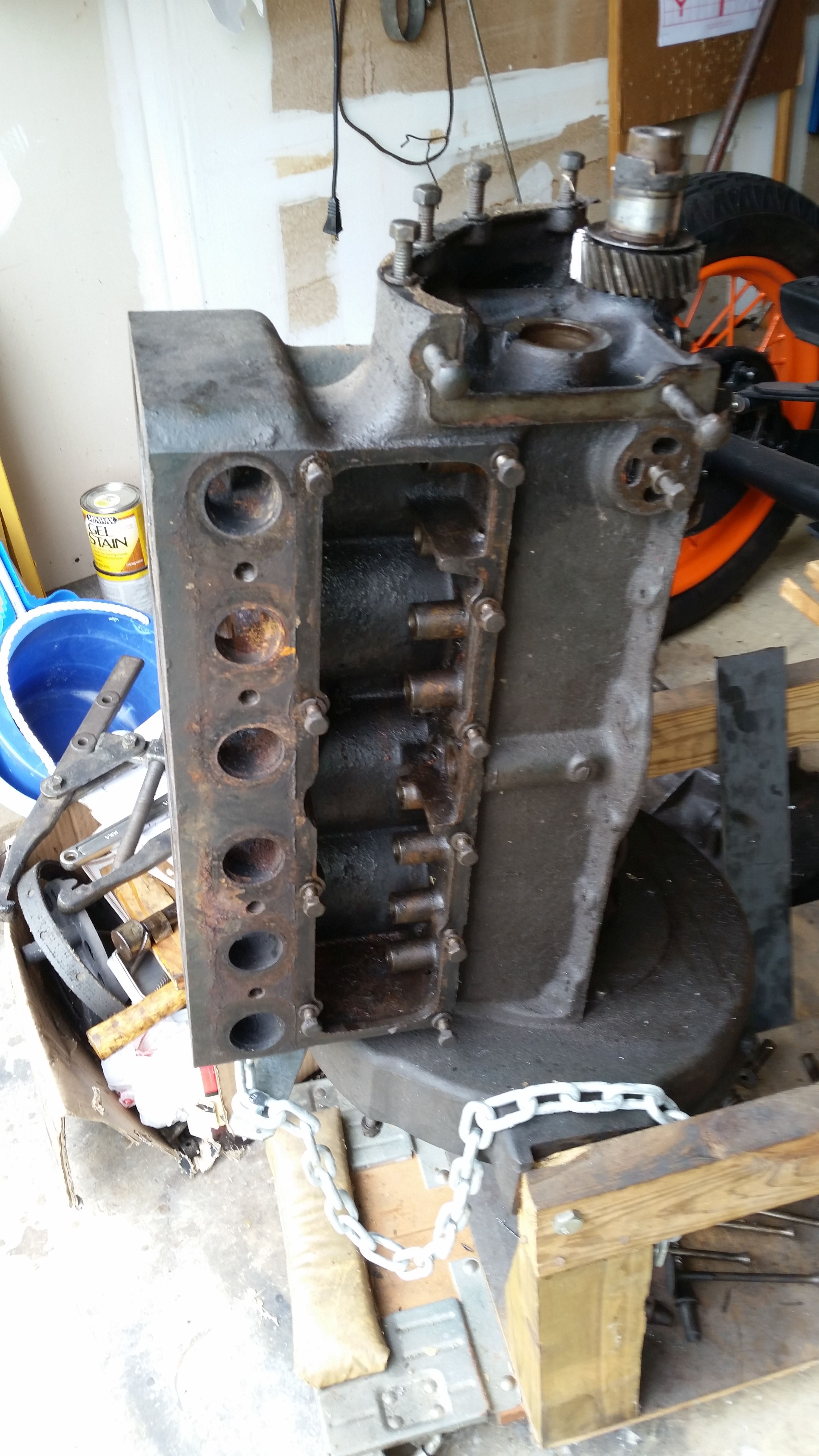

To pull the lifters, you first need to pull the cam. It gets interesting, though, as somebody paid the gravity bill... That is, the lifters need to be up to pull the cam, but they fall as soon as you let go of them, and I've only got two hands. What to do? How about if we tip it on end, like this?

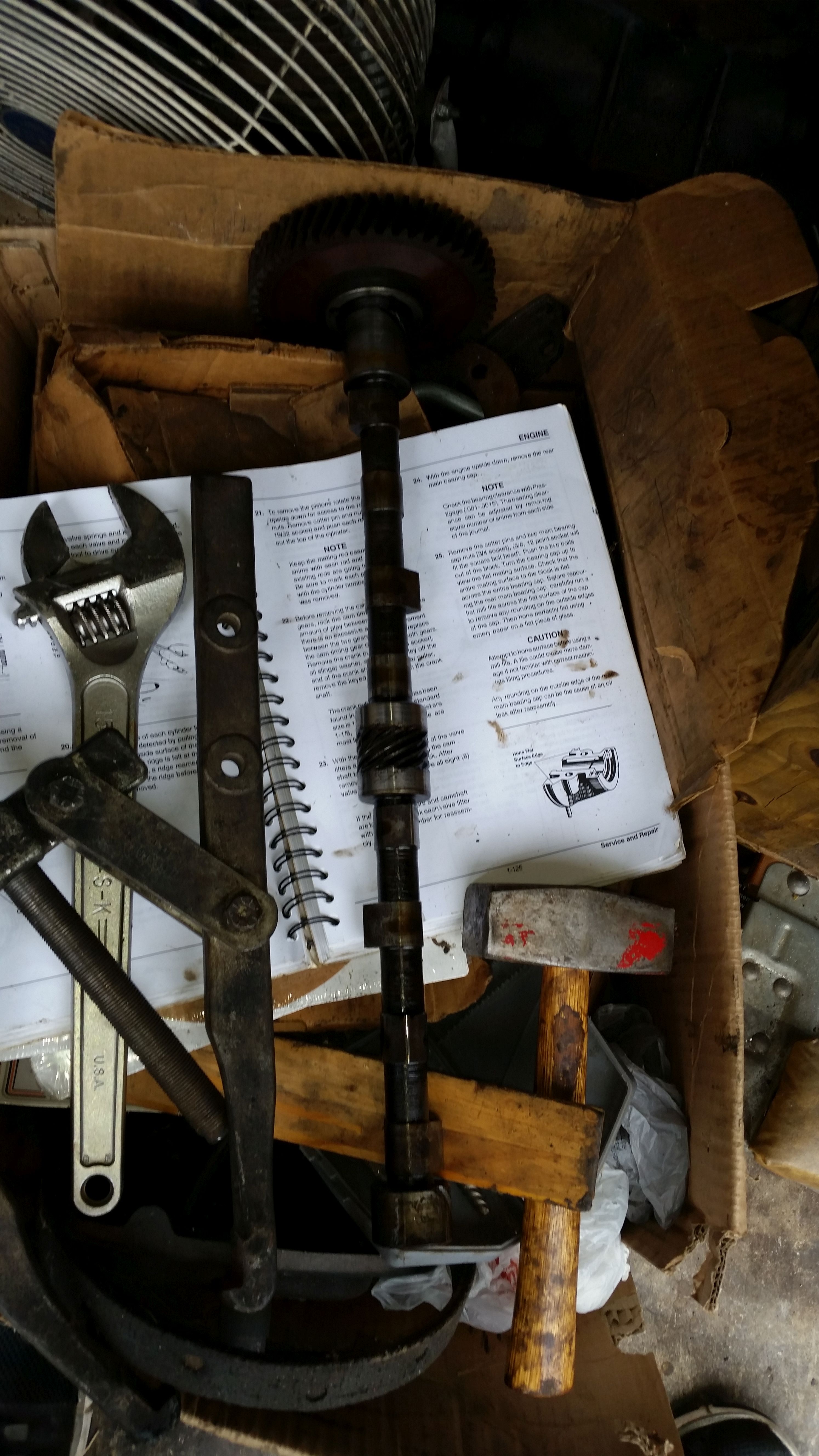

Until now, the oldest engine I've ever torn down (or helped with) was a mid-'60's engine. The cam shafts in those big block engines (heck, even in my old MG Midget - man, I miss that car) were ... well, not big, but they had some meat to them. But looking at this cam... Holy cow, it's spindly!

A quick note - the main pulley had to come off to get the camshaft out, and that was a pain. When I was done, I also tried to pull the cam pully off, but had no luck - it clearly needs replaced, though, as it's got a missing tooth. I'll ask the machine shop to do that.

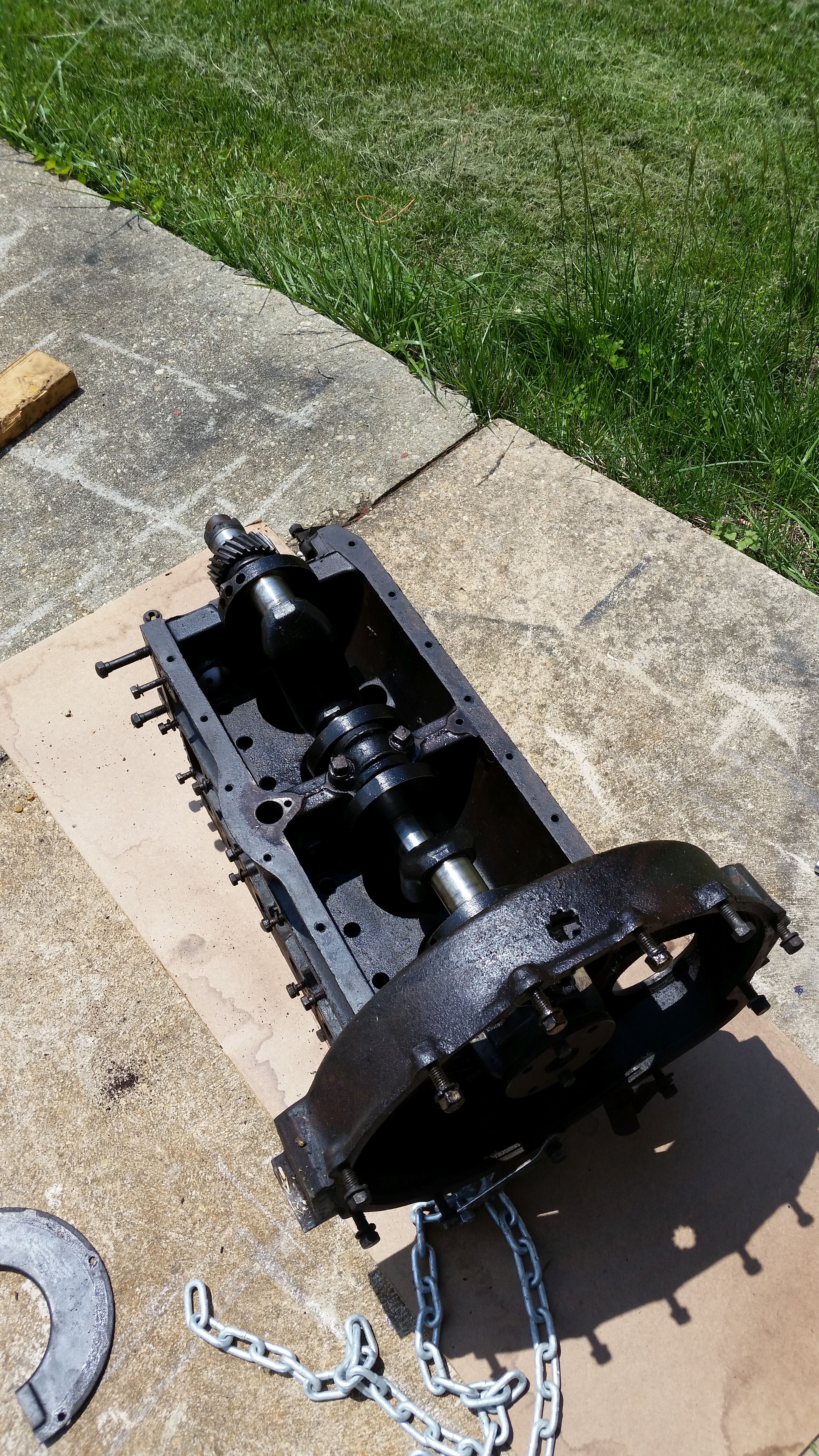

Today was another nice day - a good day to finish the engine teardown. As a quick info-pic, here's the current state of engine pieces, with one set of valves & lifters laid out to show how they go back together...

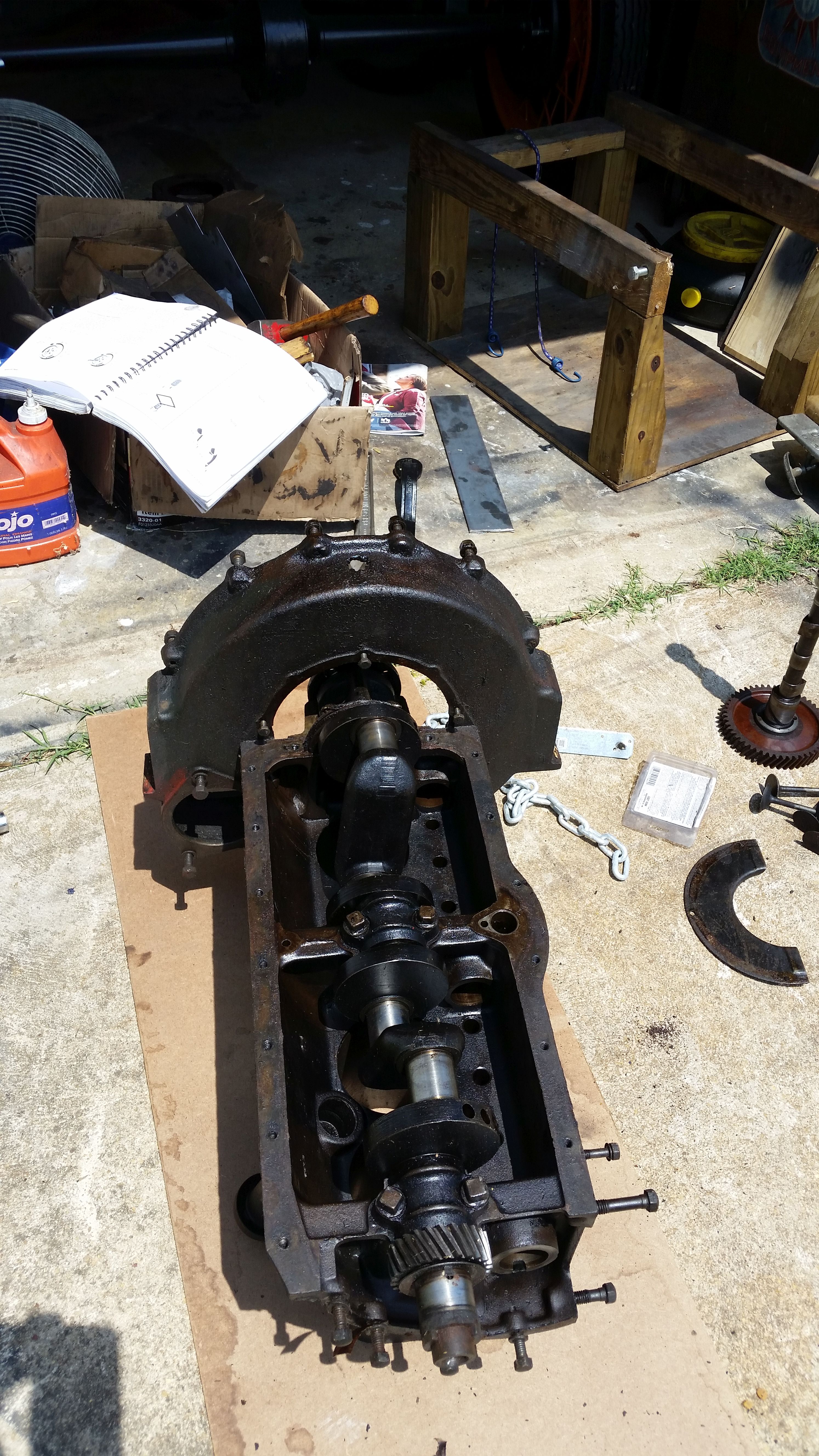

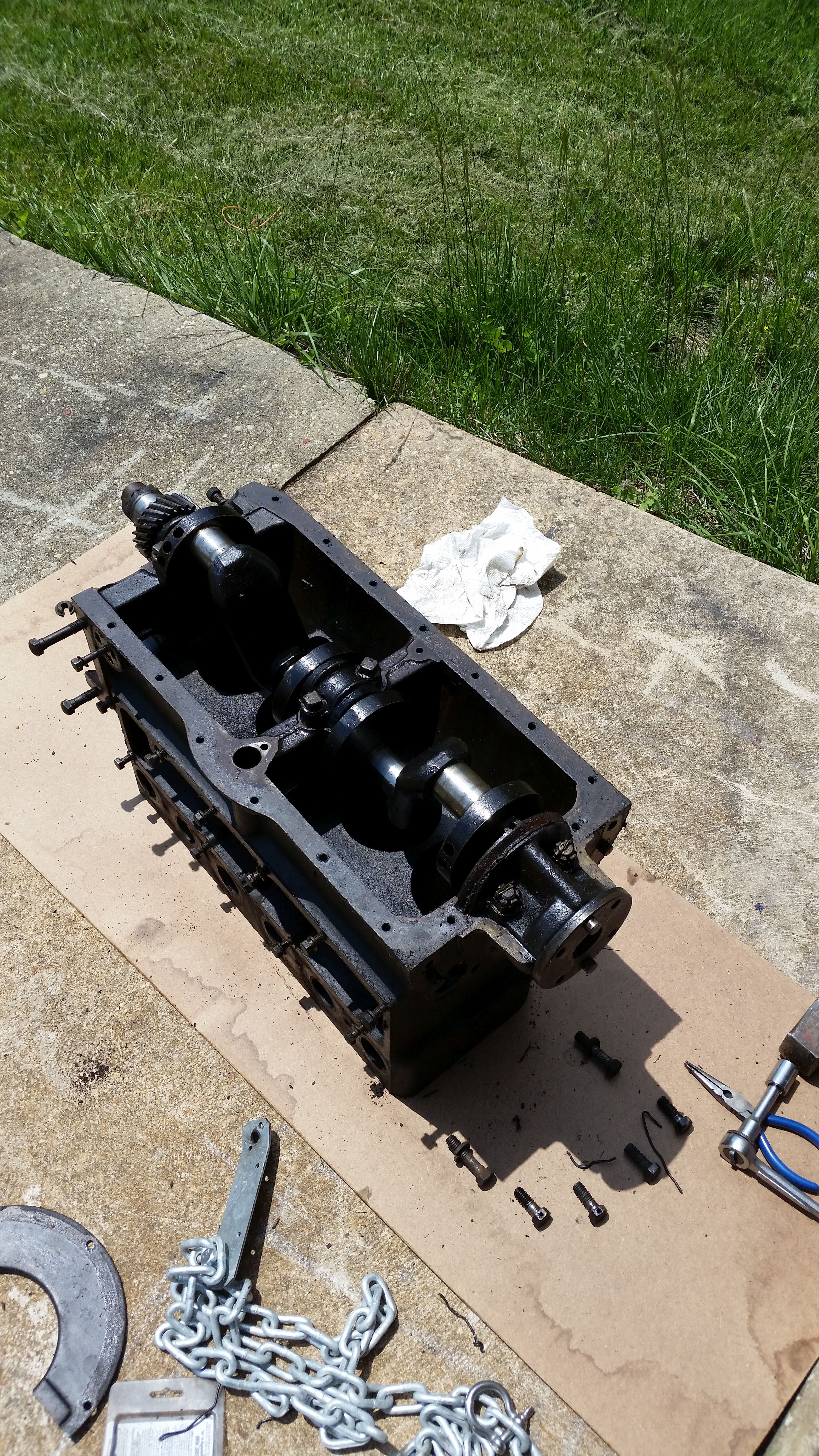

I pulled the engine out of the wooden engine stand I'd made, and carefully rolled it over (so the deck is down) onto a piece of clean masonite. That gives me a working area and reach, etc, but still protects the deck from any damage. Next step is to pull the clutch housing. First step there was to remove the inspection plate (which you can see in the earlier pic), and then cut the safety wire holding the clutch chousing bolts in place. After that, the bolts came out and the housing came off pretty easily.

The next steps of pulling the bearing caps of the three mains was pretty straight forward, although I did have to roll the block over on its side to get to some of the bolts.

Last modified on 05/31/20